|

Restoration of hydraulic brake and clutch

components for antique and custom automobiles, trucks and other vehicles

From the moment a hydraulic brake component is put into service, moisture

begins to attack and pit the cylinder walls, eventually leading to leaks and failure of

the component. Master cylinders, wheel cylinders and clutch slave cylinders can become so

pitted that they are no longer rebuildable using conventional honing techniques. In the

case of a rare or antique vehicle, these components are often hard (if not impossible) to

find and cost you dearly if you can locate them.

At Sierra Specialty Automotive, we can restore cylinders that would

otherwise be considered scrap metal to better than original

condition for a cost that is often less than you would pay for a

new or rebuilt component.

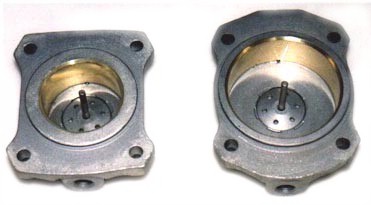

We begin by cleaning and bead blasting your original casting. It's then

precision bored and a brass sleeve is installed and honed to original dimensions. Finally,

all fluid and bleed holes are re-bored to factory specifications. The cylinder is then

ready for you to re-assemble using rebuild parts available from your local

parts store or vintage parts supplier.

You end up with new looking parts

that will last indefinitely

because the cylinder bores are now non-rusting, non-corroding brass instead of iron or

aluminum.

See a list of our prices for cylinder sleeving |