|

We are pleased to offer our program

for custom

rebuilding of early Sprite and Midget

master cylinders

|

We have made every effort to insure that all the

information presented is accurate and reliable, but we are not Spridget experts and so there

will undoubtedly be inadvertent errors that will have to be corrected as they

are found. Since we are getting much help with this project from Gerard Chateauvieux of

Gerard's Garage and

Gallery, we hasten to add that any errors will be our fault and not his. |

POST-RETIREMENT UPDATE!!!

Gerard has advised us

that he is now able to offer this service--

Email Gerard

Master Cylinders for early MG Midgets and

Austin-Healey Sprites

| Many restorers, resto-modders and customizers have converted drum-brake

Spridgets to front disk brakes using spindles, hubs and brake parts from 1098cc

cars. Others have upgraded 948cc cars with a later engine

and transmission. A few have done both. In a high percentage of cases, problems

are encountered with the combination

clutch/brake master cylinder. The 948cc drum brake cars (HAN5/6 Sprites and GAN1 Midgets) used a master

cylinder with 7/8" bores in both sides. The wheel cylinders and clutch slave

cylinder were all sized to work properly with the fluid volume and pressure

supplied by the 7/8" bore. The 1098cc disk brake models (HAN7/8 and GAN2/3) used a master

cylinder with 3/4" bores in both sides, and the front calipers, rear wheel

cylinders, and clutch slave cylinder were all sized appropriately.

Nowadays, 3/4" master cylinders are very difficult to find, so most people

are forced to use the 7/8" master cylinder in their conversion. The area of the

7/8" piston is about 36% greater than the area of the 3/4" piston. This means

that the pedal effort required for clutch and brake operation is 36% higher with the larger

cylinder. It also means that clutch slave piston travel is 36% greater.

The increase in required pedal effort results in significant safety and

drivability issues, and the increased slave piston travel can cause mechanical problems with the

throwout linkage.

This is well illustrated in the photo below, sent to us by a customer with a 1275

engine and transmission. After installing a master cylinder with a 3/4" clutch

bore, this customer reported a great improvement in clutch pedal feel and

operation.

|

| Owners who have done both the brake and running gear conversions would be

well served by a stock 3/4" master cylinder, IF they could find one. But the

many owners who have done only one or the other require a cylinder with

different-sized bores, which has never been available--until now. We have developed a program to convert 7/8" master cylinders to 3/4" on

either the brake or clutch side, or both. These conversions are accomplished

using custom-manufactured 3/4" pistons and stock Spridget rebuild parts. They

are every bit as safe and reliable as the original cylinders, and are set up to

suit the exact needs of each customer. Since they use stock rubber parts, they

can easily be serviced in the future as needed. Shown below are the three

variations of this cylinder. The one on the left is sized for drum brakes and

1098 clutch, the one in the middle is for disk brakes and 1098 clutch,

and the one on the right is for disk brakes and 948 clutch.

|

| Our friend and customer Gerard Chateauvieux provided the initial impetus for this

program, and has written his own

description of the project on his website. Gerard's site,

Gerard's Garage and Gallery, is an

excellent resource for owners of Little British Cars, especially the MG Midget

and Austin-Healey Sprite. |

"Roadstar" Cylinders

| There are a large number of cylinders of both sizes that were serviced by a

company in Sacramento CA called Roadstar. Their process involved boring the

castings larger by about 0.025" and fitting their own custom pistons and rubber

parts. Here at Sierra Specialty Automotive, we could easily sleeve these castings to

the Roadstar dimensions. Apple

Hydraulics in New York bought out Roadstar and stocks the oversized

rubber parts. If a "Roadstar" cylinder still has a clean bore with no

pits, one could get new rubber from Apple and do an acceptable rebuild.

However, we much prefer to sleeve cylinders

back to the original diameters and fit them with correct pistons that use stock

rubber parts. While it is certainly possible for us to sleeve a Roadstar

7/8" cylinder down to 3/4", it involves additional machining and significantly

more expensive tube stock so we prefer not to do so. We almost always have stock

cores that we can exchange at no charge in this situation. We then sleeve the

Roadstar cylinders to 7/8" for MGA and drum-brake Spridget customers. 3/4" Roadstar

cylinders can easily be restored to 3/4".

Shown below is a cylinder with the Roadstar tag. In many

cases the tags are missing. Most of them are also stamped with a number in

digits 1/4" tall on the side opposite the tag.

|

Original and Roadstar Piston Variations

| This photo shows the different pistons we have seen so far in

these cylinders. We believe the black coated pistons on the far left and far

right are from newer OEM replacement cylinders. The plain steel 7/8" piston

second from left is probably from an original cylinder. Not shown is a plain

steel version of the OEM 3/4" piston. Note that the original pistons of both

sizes have a seal locating rib under the head, which interlocks with a matching

groove in the original seals. The seals used on the Roadstar pistons had no such

groove and were held in place by the second rib, which is nearly full diameter. The

Roadstar pistons measure about 0.775" and 0.900" in diameter. |

photo courtesy of

Gerard's Garage

Technical Issues

| At first glance, it might seem a simple thing

just to make 3/4" pistons, but the situation is a little more complicated. In

addition to the obvious difference in diameter, there are two other important

differences. The 3/4" pistons are about 0.050" shorter, and the pushrod socket

is about 1/2" shallower than the 7/8" pistons. The fluid ports in the bottom of

the reservoir of the 3/4" casting are drilled to match the shorter piston

length, and the pushrods used in the later cars are 1/2" shorter as well. Click

on a thumbnail image below for a larger view. The pushrod lengths are 3-11/16"

for the disk brake cars and 4-3/16" for the drum brake cars. Only the longer

pushrods are currently available from the usual vendors, but we have short

pushrods, pictured below at right, for sale to our sleeving and rebuilding customers. Note that

master cylinders salvaged from MGA cars may include MGA pushrods, which are

similar to Spridget pushrods except that they are 4-7/16" long and have a

1/2" hex instead of 3/8". |

|

port spacing varies to match piston length |

photo courtesy of

Gerard's

Garage |

our new short pushrods |

click on a thumbnail for a larger

view

| Some owners will have a 3/4" Roadstar casting and need pistons for

both sides, and some owners will have 7/8" castings and need pistons for one or

both sides. We can accommodate the different castings with our pistons by making

them in both lengths. The pushrod issue cannot be solved quite so simply. Since

the 3/4" piston is smaller in diameter, the pushrod socket is also smaller in

diameter, by about 1/16", and there is less room for the up-and-down

articulating motion of the pushrod as the pedal is depressed. If the socket were

drilled deeper to receive the longer pushrod, the pushrod would bear against the

bottom of the socket as the clutch pedal is depressed. Short pushrods are, therefore, required for proper

operation. You can shorten your drum brake or MGA pushrods by cutting them to the

3-11/16" length and grinding the round profile on the end. We will be happy to

shorten pushrods at no charge for our sleeving and rebuilding customers.

Send us your old, rusted cylinder and tell us what brakes

and running gear you have. We'll build it into a custom unit that will

operate your brakes and clutch with the same pedal feel and system performance

that was present in the original cars.

|

Springs

| There are also differences between the return springs in

the 948 and 1098 cylinders. The significant difference is in the diameter of the

end of the spring where it fits over the residual valve. The plastic valve used

in the later cars is larger than the stamped metal valve body used in the early

cylinders, so the later return springs are larger at one end rather than

tapering to smaller diameters at both ends. The double-tapered 948

spring will work perfectly in a 3/4" clutch-side bore, but will not work as is

in a 3/4" brake-side bore. The 948 spring can be replaced with a new 1098

spring, part number

181-710 at Moss

Motors, or it can be opened up at one end with pliers until the plastic valve

fits and is roughly square with the spring. Pictured at left is a new 948

spring with the metal stamping fitted, at middle is a new 1098 spring with

plastic valve, and at right a re-worked 948 spring. We install a new or a very

good used 1098 spring in the brake side of cylinders that we sleeve and rebuild,

and offer new 1098 springs to customers who take sleeving only for $6. |

| 2011. As of Mid-September, there is still no estimated

re-stocking date. We are currently having to modify 948 springs for the

brake side of our conversions. |

Cylinder Finishes

|

Many customers inquire about finishes

that are resistant to brake fluid. We have used

VHT Brake Caliper,

Drum, and Rotor paint with good results. Start with a clean casting,

mask plug ports and gasket surfaces, apply two thin coats, allow to dry

overnight, then cure in an oven at 300 degrees for an hour. There is minimal odor since most of the volatiles go away during the

air-dry, so you can do it in the kitchen without triggering a divorce. From our

experience, one can will do about four typical master cylinders. It makes a very

tough coating that is very resistant to brake fluid. We understand that original Spridget master cylinders were

bare metal, or "rust" as one source put it, so the Cast Aluminum paint would probably be most "correct"

although it is much brighter than cast iron. Our

personal preference is the Satin Black color. We try to keep in stock Gloss Black, Satin Black,

Bright Blue, Real Orange, Bright Yellow, Cast Aluminum, and Real Red, and we will paint

and bake your cylinder for $25 if you prefer not to do it yourself. Painting

should be done after sleeving. Plating or powder-coating should be done before

sleeving. See our

Brake FAQ entry for more information about painting.

Click on the thumbnails below to see cylinders with

bare castings rebuilt and

ready to install, and a casting

finished in Satin Black.

|

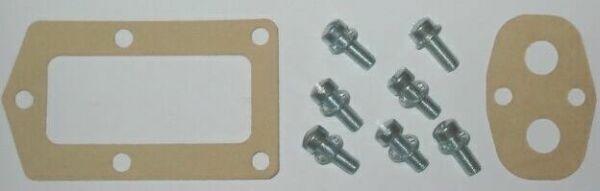

We Include with Your Cylinder...

|

...new gaskets for the lid and the piston

retaining cover. We also include new fillister-head machine screws and

internal-tooth lockwashers as used originally. Current price from the usual

vendors for the gaskets and screws is over $12.00. Our price? Zero...zip...nada.

We also include a new Lockheed filler cap

with each complete rebuild job, or sell them with sleeving for $7. This offer is

subject to availability of new caps.

|

Rear Brakes

| Owners who convert to the disk front brakes should also convert

the rear drum brakes to match. Gerard has written up a

great discussion of this on his website, and we strongly encourage you to read and

heed. |

On the Origin of Species

|

The first master cylinder of this style was

used in the MG Magnette ZA and ZB, and TR2-early TR3. The most obvious

difference is that the Spridget/MGA cylinder lid is retained with 5 capscrews,

while the Magnette/TR lid has 4 screws. The Spridget/MGA casting number is

38183, and the Magnette/TR casting number is 31448. Other differences are that

the Magnette bore is about 5/16" deeper and the outlet ports are threaded

3/8"-20 (Whitworth) rather than 3/8"-24 (Imperial). The Magnette cylinder is

assembled with the residual valve for the brakes on the right side looking into

the bores, while the Spridget cylinder is assembled with the valve on the left.

The Magnette uses the bellows boots shown rather than the flat boots used on the

Spridget cylinders.

All internal parts and the front piston retaining plate are the

same between the two cylinders, as is the mount bolt spacing.

If a Magnette or TR is re-fitted with brakes or clutch that

originally used a 3/4" master cylinder, our conversion would be applicable to

this cylinder.

|

Pricing

| The vast majority of these old cylinders are rusted and pitted, and require

sleeving to restore them to reliable, safe operating condition. Accordingly, we

start with the assumption that the cylinders we convert will be sleeved. Our

standard sleeving price of $145 for double-bore cylinders applies regardless of

original or finished size. We also offer complete rebuilding, which includes all

rubber parts and assembly in addition to sleeving, for $205. Again, this price

applies regardless of original or finished size. Add to these prices $40 per

piston for one or two as needed. Note that for California customers, we must

charge tax on rebuilding as well as the cost of pistons. We are not required to

charge tax on sleeving only, or on sales outside California. All sleeved cylinders are supplied with new

gaskets, fillister head machine screws, and internal tooth lockwashers. Rebuilt

cylinders are also supplied with a new Lockheed filler cap (when available). Pushrod shortening

service is included at no charge with sleeving or rebuilding. New correct-length

pushrods with jam nuts are $12 each. Sleeving customers can buy new filler caps for

$7. The best new cylinder currently available from the usual US vendors is a Lucas

replacement for the 7/8" master cylinder, priced typically at about $300. While

it is perfectly suited to drum-brake Spridgets with original running gear, it is

not at all suited to 1098 Spridgets nor to an upgraded older car. (There is also

a 7/8" off-shore repop available for about $210, but we have heard of quality

issues with these.) Your cylinder

sleeved and rebuilt by Sierra Specialty Automotive will cost $245 if fitted with

one new piston, and $285 if fitted with two--That's still less than the

good replacement which does not meet your needs. If you wish to buy a complete

cylinder outright, add our core charge of $75.

We ask that you send your cylinder complete, but drained of fluid, and

double-wrapped in plastic bags to prevent fluid leakage from the package.

|

|